IndustryOS® & Manufacturing Excellence FAQs

IndustryOS® and Manufacturing Excellence: Frequently Asked Questions (FAQ)

What exactly is IndustryOS® and how does it function as a Digital Twin Platform?⇲

Core Functionality:

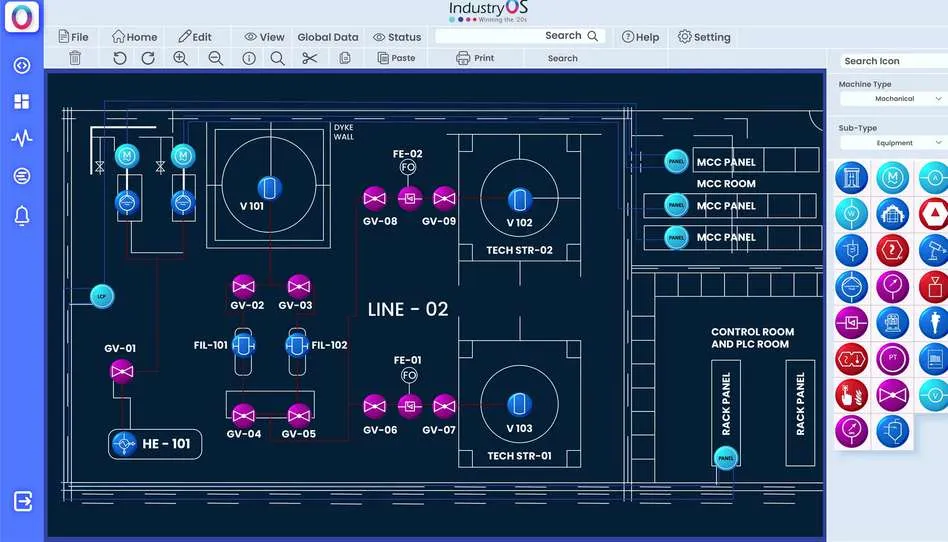

- Virtual Representation: IndustryOS® creates a virtual representation of physical assets, processes, and entire systems, based on an ANSI standard model.

- iLOL® Foundation: The platform is built over iLOL® (Information Layered over Layout), which allows the entire factory floor to be digitally replicated within the software.

- Real-Time Mirroring: Utilizing IT/OT Integration, IndustryOS® mirrors its real-world physical counterpart in real-time, integrating dynamic data from sensors and IoT devices. This integration ensures seamless communication between enterprise-level systems (IT) and industrial processes (OT).

- Unified Platform: Unlike disparate systems, IndustryOS® integrates key operational areas—Process, Quality, Maintenance, ESG, and EHS—into one cohesive software environment.

- Data Integration: It integrates static data (like design specs and P&IDs), workflow data, and dynamic manufacturing data to solve a multitude of use cases on a single platform

How does IndustryOS®⇲ represent the future of manufacturing excellence⇲ and build modern smart factories?

Building the Smart Factory of Tomorrow:

- AI and ML Integration: The platform integrates AI and Machine Learning (ML) to enhance decision-making with predictive analytics and continuous learning from real-time data. This includes running MLOps at the edge to predict, classify, and detect anomalies.

- Complete Digitalization: IndustryOS® enables the complete digitalization of entire facilities, seamlessly integrating machines, people, processes, and safety functions.

- Unified Decision Making: By unifying operational areas, Sparrow became the only company in India (as of Jan 2025) to integrate digital twins with Process, Quality, and Maintenance solutions.

- Driving Efficiency: Through real-time tracking, it maximizes process efficiency, enhances plant productivity, and refines operational parameters systematically. This leads to key outcomes such as a 20%+ OEE Boost and a 30% reduction in unplanned downtime.

- Data-Driven Innovation: The platform’s advanced analytics and real-time data access provide data-driven insights for improved business strategies and continuous performance monitoring.

Why is IndustryOS®⇲ a superior choice compared to products offered by traditional global companies like Siemens, Aveva, and Rockwell?

Sparrow delivers solutions that are designed to be better than offerings from traditional companies like Siemens, Aveva, and Rockwell, particularly due to its specialized approach and focus on the unique challenges of developing economies like India.

Building the Smart Factory of Tomorrow:

- OEM Agnostic Foundation: IndustryOS® is OEM Agnostic. It provides seamless industrial connectivity and can quickly connect to any make PLC/DCC, or any hardware or software system using prebuilt drivers. This ensures clients are not bound to a specific vendor platform.

- Speed and Affordability: Sparrow offers faster implementation for quick deployment and realization of benefits. Furthermore, our solutions are cost-effective and affordable, making them an attractive option for small and medium-sized enterprises (SMEs) with budget constraints.

- Deep Sector Customization: While traditional companies are often monoliths, Sparrow provides deep sector customization. Our solutions are highly tailored to meet the specific needs of diverse industries, including chemical, FMCG, steel, cement, aluminum, pharma, and oil & gas.

- Local Expertise: Headquartered in India, Sparrow possesses a deep understanding of the local market and regulatory landscape, ensuring solutions are effective and compliant with Indian standards. We serve over 415+ clients across various industries.

- Unified Digital Twin Integration: IndustryOS® offers a robust digital twin platform that seamlessly integrates across Process, Quality, Maintenance, and EHS—a comprehensive integration that provides unified, real-time data for advanced analytics, which is crucial for achieving true operational excellence.

What measurable operational improvements can organizations expect from deploying IndustryOS®?

Sparrow delivers solutions that are designed to be better than offerings from traditional companies like Siemens, Aveva, and Rockwell, particularly due to its specialized approach and focus on the unique challenges of developing economies like India.

Key Competitive Advantages

- OEM Agnostic Foundation: IndustryOS® is OEM Agnostic. It provides seamless industrial connectivity and can quickly connect to any make PLC/DCC, or any hardware or software system using prebuilt drivers. This ensures clients are not bound to a specific vendor platform.

- Speed and Affordability: Sparrow offers faster implementation for quick deployment and realization of benefits. Furthermore, our solutions are cost-effective and affordable, making them an attractive option for small and medium-sized enterprises (SMEs) with budget constraints.

- Deep Sector Customization: While traditional companies are often monoliths, Sparrow provides deep sector customization. Our solutions are highly tailored to meet the specific needs of diverse industries, including chemical, FMCG, steel, cement, aluminum, pharma, and oil & gas.

- Local Expertise: Headquartered in India, Sparrow possesses a deep understanding of the local market and regulatory landscape, ensuring solutions are effective and compliant with Indian standards. We serve over 415+ clients across various industries.

- Unified Digital Twin Integration: IndustryOS® offers a robust digital twin platform that seamlessly integrates across Process, Quality, Maintenance, and EHS—a comprehensive integration that provides unified, real-time data for advanced analytics, which is crucial for achieving true operational excellence.

What measurable operational improvements can organizations expect from deploying IndustryOS®?

| Operational Domain | Improvement Metric | Expected Impact/Result |

|---|---|---|

| Operational Efficiency (Process) | 20%+ OEE Boost | Achieves operational excellence by driving efficiency and maximizing asset utilization (More Output, Same Resources) |

| Maintenance/Asset Reliability | 30% Less Downtime / 30% Reduction in Unplanned Downtime | Predictive insights slash unplanned stops, protecting the production schedule and maximizing uptime/revenue |

| Quality Control | 25% Improvement in First Pass Yield | Reduces rework and scrap through real-time quality control and analytics (Lower Costs, Higher Quality) |

| EHS/Safety | 45% reduction in workplace injuries | Companies using Sparrow's EHS software help propagate a safer environment for their workers. |

| Accident Costs | 30% reduction in accident costs | Reduction in financial losses associated with incidents. |

| ESG Reporting | 95%+ ESG Reporting Compliance | Builds investor and regulatory trust with audit-ready sustainability data and transparent operations |

How does IndustryOS® leverage AI and IT/OT Integration to achieve its predictive capabilities?

- IT/OT Convergence: Sparrow’s software solutions transform Operational Technologies (OT) and integrate them into the existing IT architecture. This complete package ensures seamless communication, allowing the platform to collect, standardize, and store data from all devices and systems, resulting in normalized data for accurate, unified insights.

- AI-Driven Analytics: The platform uses its proprietary AI Engine and AI/ML integration to transform this real-time data into predictive insights. For instance, our AI-driven Predictive Maintenance Software leverages AI and IoT to anticipate failures, reduce downtime, and optimize asset performance. In Quality, this enables AI-Driven TQM (Total Quality Management) by using process-centered information layers for predictive and optimized quality, including tracking metrics like Cp and CpK.

What EHS and Sustainability solutions are integrated within the IndustryOS® platform?

EHS Management: Sparrow offers an extensive 50+ EHS Software Suite designed to reduce hazards and promote workplace safety. Key modules include:

- Risk Mitigation: Process Safety Management (PSM), Hazard Identification and Risk Assessment (HIRA), Job Safety Analysis (JSA), and Management of Change (MOC) Software.

- Compliance & Workflow: Permit to Work (PTW) Software, LOTO Management Software, Compliance Management Software, and Audit Management Software.

- Monitoring & Response: Incident Management Software and EHS KPI Dashboards for real-time analytics.

- GHG Accounting & Assurance: Automated accounting for Scope 1, 2, and 3 emissions.

- Reporting: Simplified compliance with BRSR Reporting Solutions and support for other global frameworks (GRI, CDP, SASB).

- Assessment: Conducting Life Cycle Assessment (LCA) and Materiality Assessment.

Which industries benefit most from the custom-developed solutions offered by Sparrow and IndustryOS®?

Sparrow’s solutions are highly customizable, leveraging core engineering expertise and custom development capabilities to meet specific client needs. We specialize in digital transformation across several heavy and process industries:

- Chemical Manufacturing: Key use cases include real-time sensor data analysis, Critical Interlocks & Alerts, OEE, Traceability, and advanced EHS risk systems like HAZOP and LOPA.

- Pharmaceutical (Pharma): Digitalizing process, quality, and maintenance functions to ensure consistency and compliance.

- FMCG: Maximizing process efficiency, quality control, and reducing waste.

- Other Sectors: Cement, Mines, Oil & Gas, Steel, and Aluminum.

Our core strength lies in understanding your chemistry and processes, utilizing a dedicated team of over 30 Field Engineers to ensure significant added value and accelerated results.