Standardizing Digital Transformation with SIRI (Manufacturing)

Standardizing Digital Transformation with SIRI (Manufacturing)

Smart Industry Readiness Index

Your Gateway to Industry 4.0 Journey

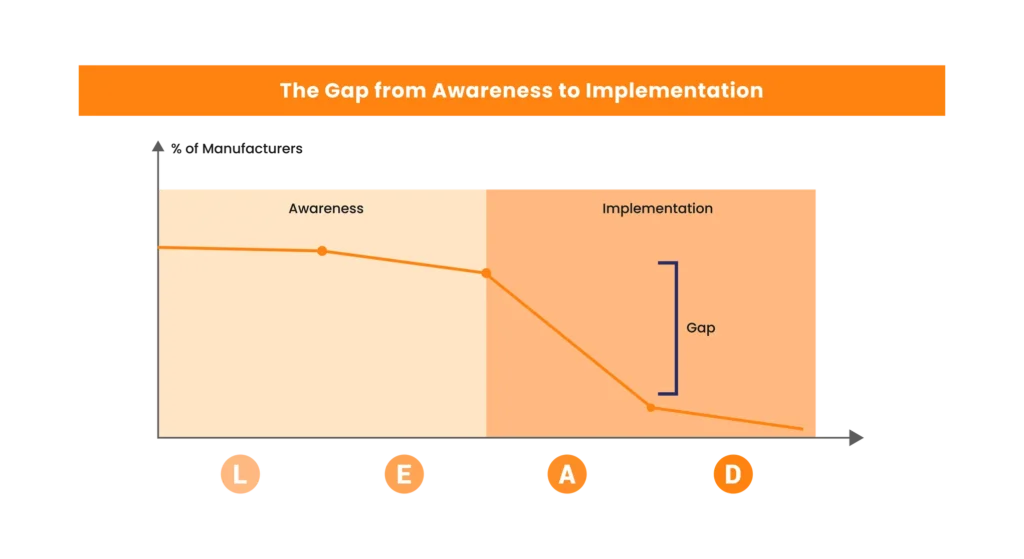

70% of digital transformations fail from weak strategy, misaligned leadership, resistance to change, and lack of clarity.

While 61% of top executives consider digital transformation a priority, few have a clear roadmap to achieve it.

The Smart Industry Readiness Index (SIRI) assessment helps bridge this gap

Strategic Snapshot

In an era where Industry 4.0 often represents an ambiguous and intimidating paradigm shift, the Smart Industry Readiness Index (SIRI) provides the world’s standardized first independent, methodology for manufacturers to translate abstract digital goals into a tangible, data driven, and strategic roadmap.

Developed by the Singapore Economic Development Board (EDB) in partnership with global industry leaders and endorsed by the World Economic Forum (WEF), SIRI serves as a universal compass for companies of any size or sector aiming to navigate the complexities of digital transformation.

The key findings of this analysis reveal that SIRI’s principal value extends far beyond a simple maturity score; its core function is to catalyse strategic alignment. By establishing a common, organization-wide language for digital transformation, SIRI bridges the critical gaps between operational technology (OT) and information technology (IT), and between the shop floor and the C suite, ensuring that all stakeholders are working from a unified blueprint.

SIRI is not a one-time audit but a governance tool for ongoing digital transformation, helping manufacturing leaders chart a clear, confident, and value driven path through Industry 4.0.

The industry 4.0 Challenge: From Buzzword to Business Value

The Fourth Industrial Revolution, or Industry 4.0, signals a fundamental shift in manufacturing, offering unprecedented gains in efficiency, flexibility, and speed through the convergence of physical and digital worlds.

Yet for many leaders, this path is clouded by technological complexity and strategic uncertainty, with a crowded landscape of solutions AI, IIoT, digital twins, and big data analytics each promising transformation This technological abundance often leads to confusion and inaction. Many organizations struggle to understand what Industry 4.0 means for their specific operations and how to begin their transformation journey.

Without a clear starting point or structured methodology, companies risk costly investments in technologies that deliver little value or remain isolated pilots.

A key challenge is the lack of shared understanding across the organization, creating misalignment between technology initiatives and business objectives.

What is SIRI Assessment ⇲

The Smart Industry Readiness Index (SIRI) is a global framework and assessment tool that helps manufacturers evaluate digital readiness for Industry 4.0. Developed in Singapore and endorsed by the World Economic Forum, it offers a standardized approach for companies of any size to start, scale, and sustain transformation.

By assessing key processes, technologies, and enablers, SIRI pinpoints digital maturity and the steps toward smart factory capabilities. This report outlines the assessment process, its impact on productivity, efficiency, EHS, and sustainability, expected outcomes, and real-world case studies

LEAD

Learn Evaluate Architect Deliver

TIER

Today's State Impact Essential Objectives References

Sparrow helps industries adopt and execute the SIRI Assessment turning digital ambitions into clear, measurable, and value-driven transformation roadmaps.

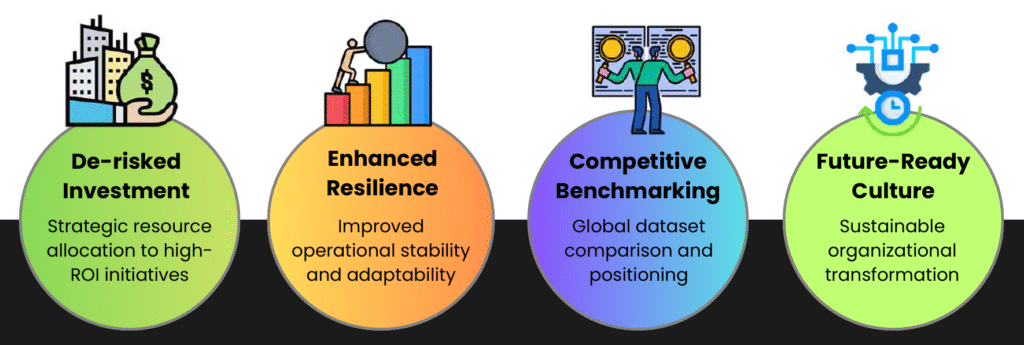

The outcomes generated by a SIRI engagement are multifaceted. They include the development of a de-risked investment strategy, enhanced operational resilience, invaluable competitive benchmarking against a growing global dataset, and the cultivation of a sustainable, future-ready organizational culture.

The two case studies presented within this report one in the oil and gas sector and another in the pharmaceutical manufacturing industry demonstrate how SIRI’s structured approach can be applied to address distinct, sector-specific challenges related to process integration, safety, and supply chain agility.

Ultimately, this report positions SIRI not as a one-time audit but as the foundational governance tool for an ongoing, dynamic digital transformation. For manufacturing leaders, it is the essential instrument for charting a clear, confident, and value-driven course through the Fourth Industrial Revolution.

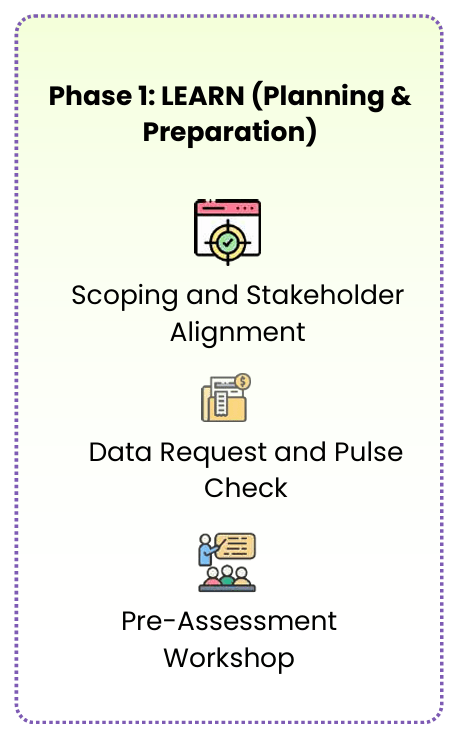

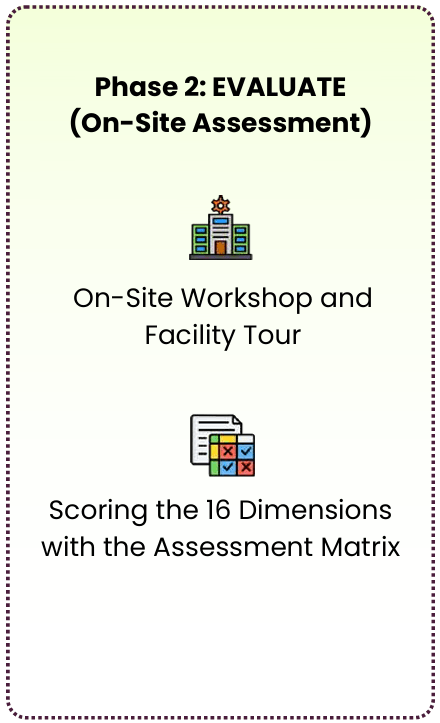

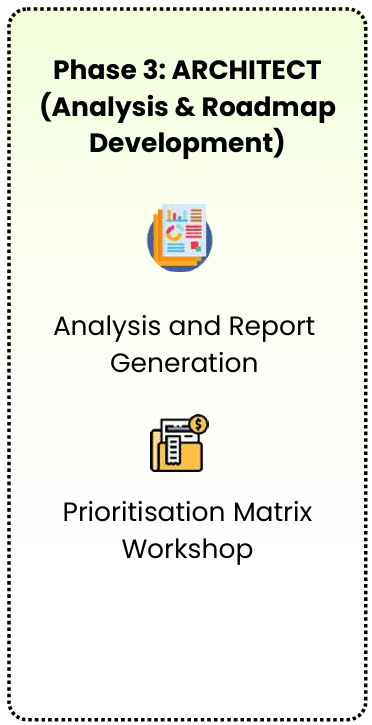

The SIRI Assessment Flow

SA itself is a structured, multi-phase process designed to be thorough yet efficient, typically completed over several weeks with minimal disruption to a company’s daily operations. The journey from initial engagement to the delivery of a strategic roadmap is visualized in the process flow below

The Architecture of Readiness:

Deconstructing the SIRI Framework

A Holistic, Three-Layered Approach

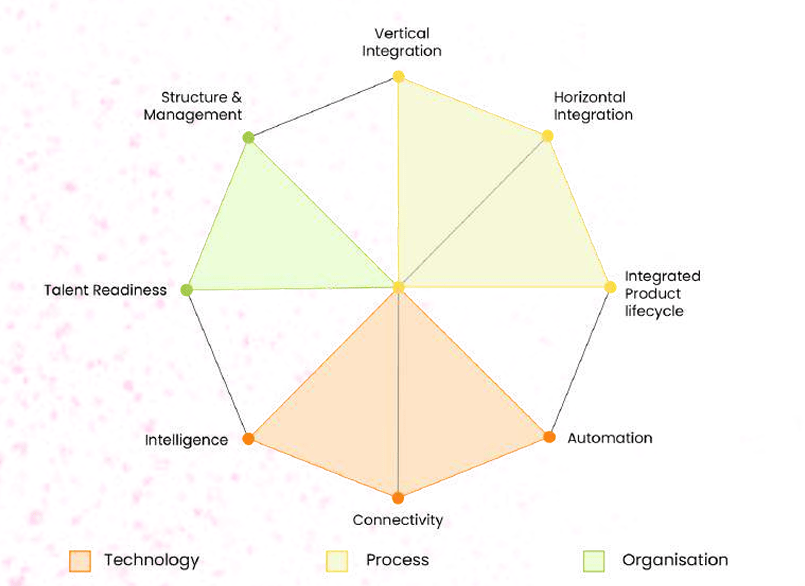

The robustness of the SIRI framework lies in its holistic, three-layered architecture, which ensures a comprehensive and balanced evaluation of a manufacturer’s readiness for Industry 4.0.

This structure is designed to prevent the common pitfall of a technology-centric approach, where companies invest heavily in digital tools while neglecting the critical processes and organizational capabilities required to unlock their full potential.

The framework is composed of three fundamental Building Blocks, which are underpinned by eight key Pillars and map onto sixteen specific Dimensions of assessment.

The Three Building Blocks: The Pillars of Transformation

The three building blocks represent the core components of any manufacturing enterprise and must be considered in concert to harness the full potential of Industry 4.0.

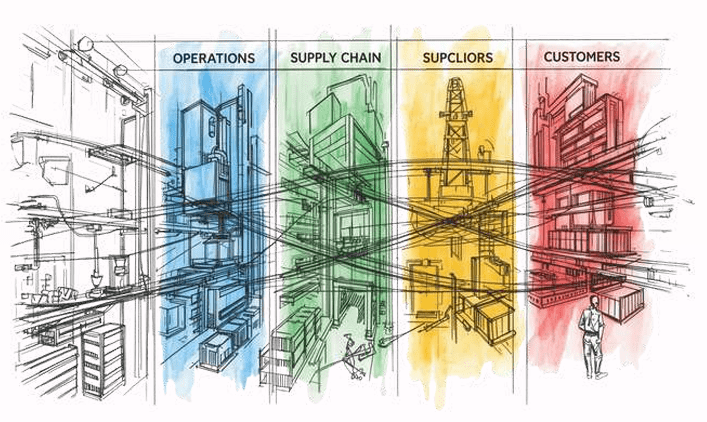

Process: This building block examines the efficiency, effectiveness, and integration of a company’s operational workflows. It assesses how well processes are connected vertically within the facility (from the shop floor to the top floor) and horizontally across the value chain (from suppliers to customers). It covers the pillars of Operations, Supply Chain, and Product Lifecycle.

Technology: This block evaluates the maturity of a company’s digital infrastructure and its capacity to leverage digital tools. It assesses the sophistication of Automation, Connectivity, and Intelligence across three distinct layers of the facility: the shop floor (production), the enterprise (business systems), and the facility itself (building management).

Organization: This block focuses on the human and structural elements essential for a successful transformation. It evaluates the readiness of the workforce and the effectiveness of the company’s management systems, covering the pillars of Talent Readiness and Structure & Management.

Smart Industry Readiness Index

D1

D2

D3

Shop Floor

Enterprise

Enterprise

Shop Floor

Enterprise

Enterprise

D13

D14

D15

D16

| Building Block | Pillar | Dimension |

|---|---|---|

| Process | Operations | D1: Vertical Integration |

| Supply Chain | D2: Horizontal Integration | |

| Product Lifecycle | D3: Integrated Product Lifecycle | |

| Technology | Automation | D4: Shop Floor Automation |

| D5: Enterprise Automation | ||

| D6: Facility Automation | ||

| Connectivity | D7: Shop Floor Connectivity | |

| D8: Enterprise Connectivity | ||

| D9: Facility Connectivity | ||

| Intelligence | D10: Shop Floor Intelligence | |

| D11: Enterprise Intelligence | ||

| D12: Facility Intelligence | ||

| Organisation | Talent Readiness | D13: Workforce Learning & Development |

| Structure & Management | D14: Leadership Competency | |

| D15: Inter- and Intra-Company Collaboration | ||

| D16: Strategy & Governance |

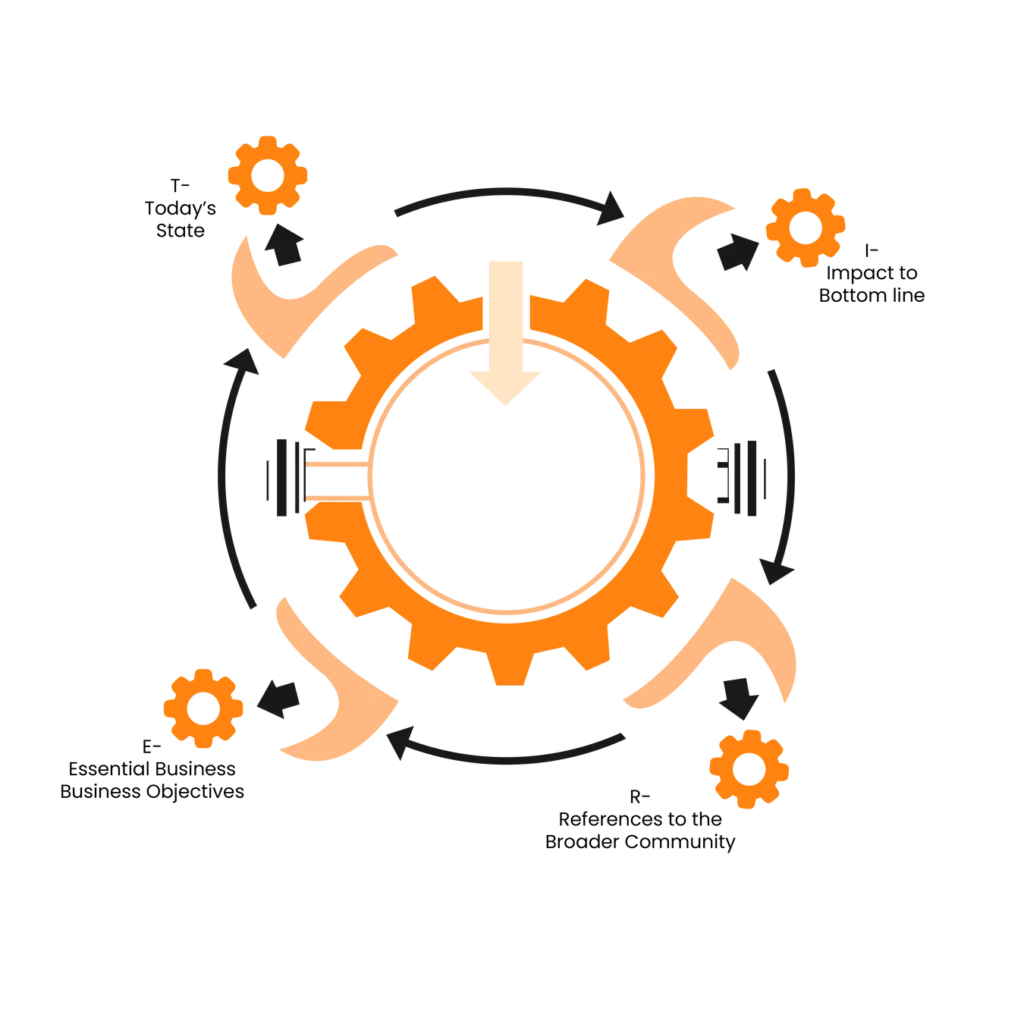

The Engine of Prioritization: The TIER Framework

The Prioritisation Matrix is powered by the four principles of the TIER framework, which ensures that the resulting roadmap is strategically aligned with the company’s unique business context

Today’s State: This is the current maturity score for each of the 16 dimensions as determined by the Assessment Matrix.

Impact to Bottom Line: This principle involves a financial analysis to determine how improving each dimension would affect the company’s key cost drivers and revenue streams.

Essential Business Objectives: This requires leadership to articulate and rank the company’s most critical strategic goals.

References to the Broader Community: This involves using the benchmarking data to understand what peers are doing. It helps differentiate between foundational improvements and differentiating investments.

The deliberate, tripartite structure of the SIRI framework forces a balanced and holistic perspective, effectively preventing the technology-centric myopia that dooms many digital transformation initiatives. It is a common failure mode for companies to treat Industry 4.0 as a series of IT projects, procuring advanced technology without fundamentally redesigning the processes that use it or upskilling the people who must operate it. SIRI’s structure, with its explicit and equally weighted building blocks of Process, Technology, and Organization, compels a comprehensive evaluation

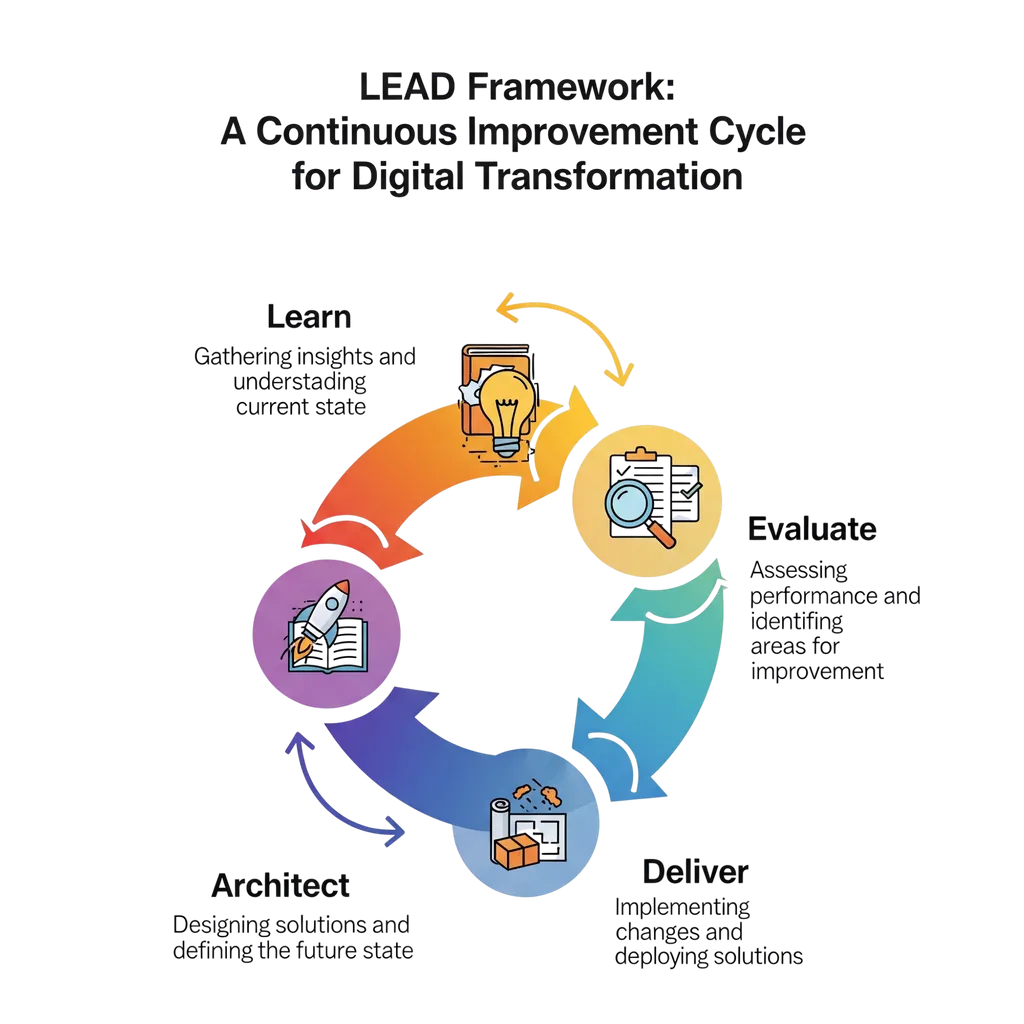

The LEAD Framework: A Cycle of Continuous Improvement

The entire SIRI transformation journey is guided by the LEAD framework, a four-step process that emphasizes the continuous and cyclical nature of digital transformation. This model positions the SA not as a one-time event but as a recurring milestone in an ongoing cycle of improvement. The four stages are:

The LEAD Framework: A Cycle of Continuous Improvement

Launched in tandem with the SIRI Framework, the Assessment Matrix is the world’s first self-diagnostic Industry 4.0 tool. The Assessment Matrix is validated by a global advisory panel of industry experts and is designed to strike a balance among technical rigour, usability, and relevance.

Companies can refer to “The Smart Industry Readiness Index” whitepaper published in November 2017 for the complete Assessment Matrix. Within the Assessment Matrix, there are six bands, in ascending order, tied to each of the 16 SIRI Dimensions.

Each band describes a specific state within that dimension. Identifying a manufacturing facility’s bands across all 16 dimensions therefore presents a snapshot of the manufacturing facility’s current Industry 4.0 maturity level. This is referred to as the facility’s Assessment Matrix Score.

Impact of SIRI on Manufacturing Operations

The Prioritisation Matrix is powered by the four principles of the TIER framework, which ensures that the resulting roadmap is strategically aligned with the company’s unique business context

Boosting Productivity and Throughput: SIRI evaluations often reveal bottlenecks or manual processes ripe for automation. By addressing gaps in areas like horizontal integration (data flow between processes), manufacturers can significantly increase output without adding new equipment. Many companies report that SIRI helped initiate leaner workflows and higher Overall Equipment Effectiveness (OEE) by guiding investments to the right areas. One medical products plant leveraged SIRI to achieve “significant improvements in speed, productivity, and quality” by targeting previously overlooked process inefficiencies.

Increasing Cost Efficiency: SIRI helps lower operating costs by pinpointing waste and improvement areas with clear ROI. For instance, SIRI might reveal that a company’s Maintenance strategy is purely reactive, leading to frequent breakdowns and expensive downtime, prompting a shift to predictive maintenance with IIoT sensors. By acting recommendations, on SIRI manufacturers commonly see cost savings materialize as lower scrap rates, reduced inventory holding costs, optimization.

Enhancing EHS Compliance and Operational Safety: SIRI’s 360-degree analysis includes Environment, Health & Safety (EHS) as a key focus area. The outcome is that many companies use their SIRI roadmap to invest in smart EHS solutions for example, deploying IoT sensors for real-time equipment condition monitoring to prevent accidents, or using digital checklists to improve compliance with safety protocols. By systematically addressing EHS-related dimensions, manufacturers can reduce accident rates and ensure regulatory compliance is maintained or exceeded

Advancing Sustainability Goals: SIRI encourages companies to consider sustainable manufacturing practices as part of their transformation. By evaluating dimensions like energy management and resource efficiency, SIRI highlights how digital technologies can support greener operations. A vice president at HP observed that SIRI “quantified the impacts of sustainability actions” and allowed them to track progress on those initiatives, putting numbers to green improvements in areas like waste reduction and carbon footprint. SIRI ensures that Industry 4.0 and sustainability go together, guiding factories to be not only smarter but also cleaner.

Expected Outcomes of a SIRI Assessment

Undergoing a SIRI assessment yields a rich set of outcomes for a manufacturing organization, which can be both qualitative (strategic) and quantitative (metric driven).

Together, these outcomes turn the nebulous challenge of “going Industry 4.0” into a concrete, manageable program with trackable progress. After a SIRI assessment, a manufacturer is equipped with both a compass and a speedometer for their digital transformation they know the direction to go, and they have the instruments to measure how fast they are improving.

| Qualitative Outcomes (Insight & Strategy) | Quantitative Outcomes (Metrics & Results) |

|---|---|

| Holistic Vision & Culture: Establishes a shared Industry 4.0 vision and language across the organization, fostering cross-departmental alignment and buy-in. | Digital Maturity Scores: Delivers an objective maturity rating on 16 dimensions of Industry 4.0 readiness, each scored in defined bands, providing a baseline to measure future progress. |

| Identification of Gaps & Best Practices: Highlights where the company lags behind industry best practices and where it excels, across processes, technology, and organization. | Benchmarking Against Peers: Through SIRI’s global database, the company can quantitatively compare itself to industry peers, providing impetus and targets for improvement. |

| Prioritized Roadmap: Produces a clear, phased action plan for transformation, aligned with business priorities, helping management allocate resources to the most impactful projects first. | Key Performance Indicators (KPIs) Improvement: Companies can track improvements in operational KPIs, such as increases in productivity, cycle time reductions, lower defect rates, and cost savings. |

| Organizational Alignment & Buy-in: The assessment process itself engages stakeholders from the shop floor to the C-suite, creating organizational alignment and breaking down silos. | Return on Investment (ROI) Projections: The SIRI report often includes high-level ROI estimates for proposed initiatives. Over time, companies can quantify actual ROI achieved. |

| Continuous Improvement & Tracking: SIRI encourages a mindset of continuous improvement, with companies institutionalizing periodic maturity assessments to keep transformation progress on the executive agenda. | Sustainability Metrics: Outcomes increasingly include quantitative measures of sustainability improvements, such as tracking energy consumption per unit, carbon emissions, or waste reduction. |

SIRI in Practice: Sector-Specific Case Studies

While the SIRI framework is universally applicable, its true power is revealed when applied to the unique challenges of specific industrial sectors. The following case studies illustrate its real-world application

Case Study 1: Driving Efficiency & Sustainability in Oil & Gas

Company Profile & Challenge

A chemicals subsidiary in the oil & gas sector, manufactures fuel and lubricant additives. Facing intense pressure to optimize complex production processes and contribute to corporate sustainability goals was challenged by:

Stringent Regulations: Adherence to rigorous safety and environmental standards.

Legacy Systems: Aging operational technology (OT) operated in silos, trapping valuable process data on the shop floor and creating a barrier to Vertical Integration.

Process Consistency: Ensuring consistent product quality and efficiency across its global network.

The SIRI Assessment Process The Company engaged a SIRI Assessor to conduct a SIRI Assessment at one of its key production facilities. The on-site workshop included the plant director, process engineers, maintenance managers, and Environment, Health, and Safety (EHS) officers. The Assesor guided the team through the 16 dimensions, mapping each to company’s core business drivers: safety, compliance, and operational efficiency.

Key Findings & Prioritized Dimensions

The Assessment Matrix revealed a clear picture of the plant’s digital maturity:

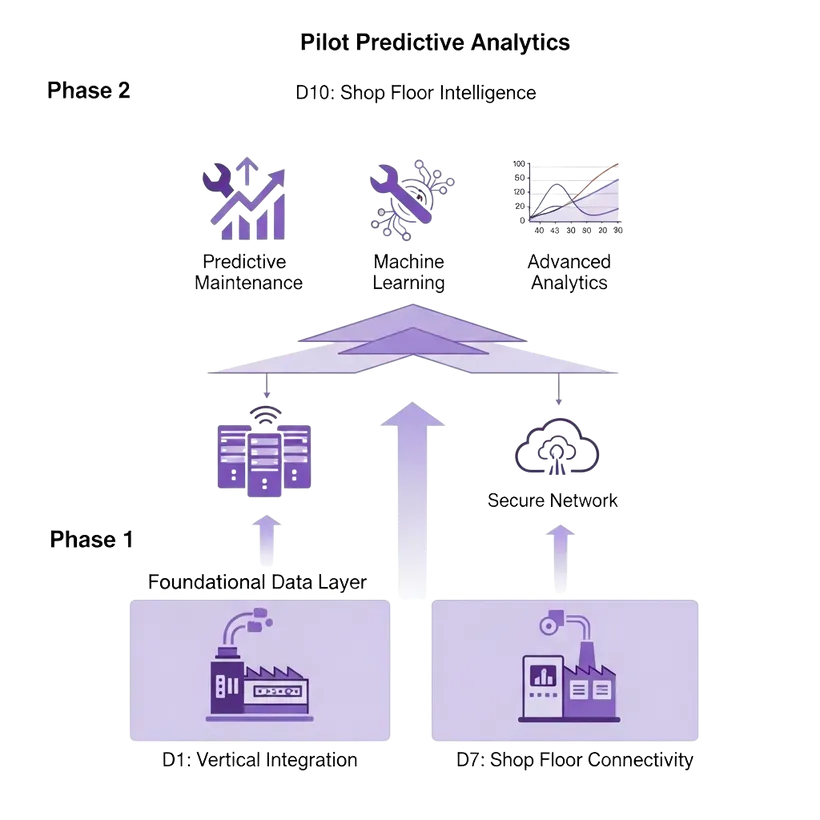

Low Scores: The facility scored particularly low in D1: Vertical Integration, confirming that data from plant-floor systems was not integrated with enterprise-level systems. It also scored poorly on D7: Shop Floor Connectivity and D10: Shop Floor Intelligence.

Key Findings & Prioritized Dimensions The Assessment Matrix revealed a clear picture of the plant’s digital maturity: Low Scores: The facility scored particularly low in D1: Vertical Integration, confirming that data from plant-floor systems was not integrated with enterprise-level systems. It also scored poorly on D7: Shop Floor Connectivity and D10: Shop Floor Intelligence. Prioritization: The Prioritisation Matrix workshop weighed the dimensions against the company’s Essential Business Objectives (improving safety, ensuring compliance, reducing energy costs). Two dimensions emerged as top

priorities:

The Prioritisation Matrix workshop weighed the dimensions against the company’s Essential Business Objectives (improving safety, ensuring compliance, reducing energy costs). Two dimensions emerged as top priorities:

- D1: Vertical Integration: Unlocking data from OT silos was the prerequisite for any advanced analytics.

- D10: Shop Floor Intelligence: The ability to move from reactive to predictive maintenance was identified as having the highest Impact to Bottom Line, directly affecting both safety and efficiency.

Transformation Roadmap & Business Impact

Based on the prioritized dimensions, the Assesor helped the Company architect a phased transformation roadmap

Phase 1: Foundational Data Layer: Focus on improving

D1: Vertical Integration and D7: Shop Floor Connectivity by investing in a modern, secure industrial network and implementing a plant-wide data historian to create a “single source of truth.”

Phase 2: Pilot Predictive Analytics: Leverage the new data infrastructure to deploy machine learning models to pilot predictive maintenance on critical assets, directly targeting D10: Shop Floor Intelligence

Expected Outcomes:

Enhanced Safety and Compliance: A projected reduction in process safety incidents and improved data integrity for regulatory reporting.

Improved Efficiency: Following the assessment, Company reported tangible gains, including a 3–5% increase in output due to decreased production variability. Energy efficiency measures led to an estimated 10% reduction in energy consumption per unit output, supporting corporate climate targets.

Strategic Compass: A Company executive noted that SIRI provided confidence they were focusing on the things that matter for long-term success and served as a useful framework to guide our future decisions to deliver sustained impact.

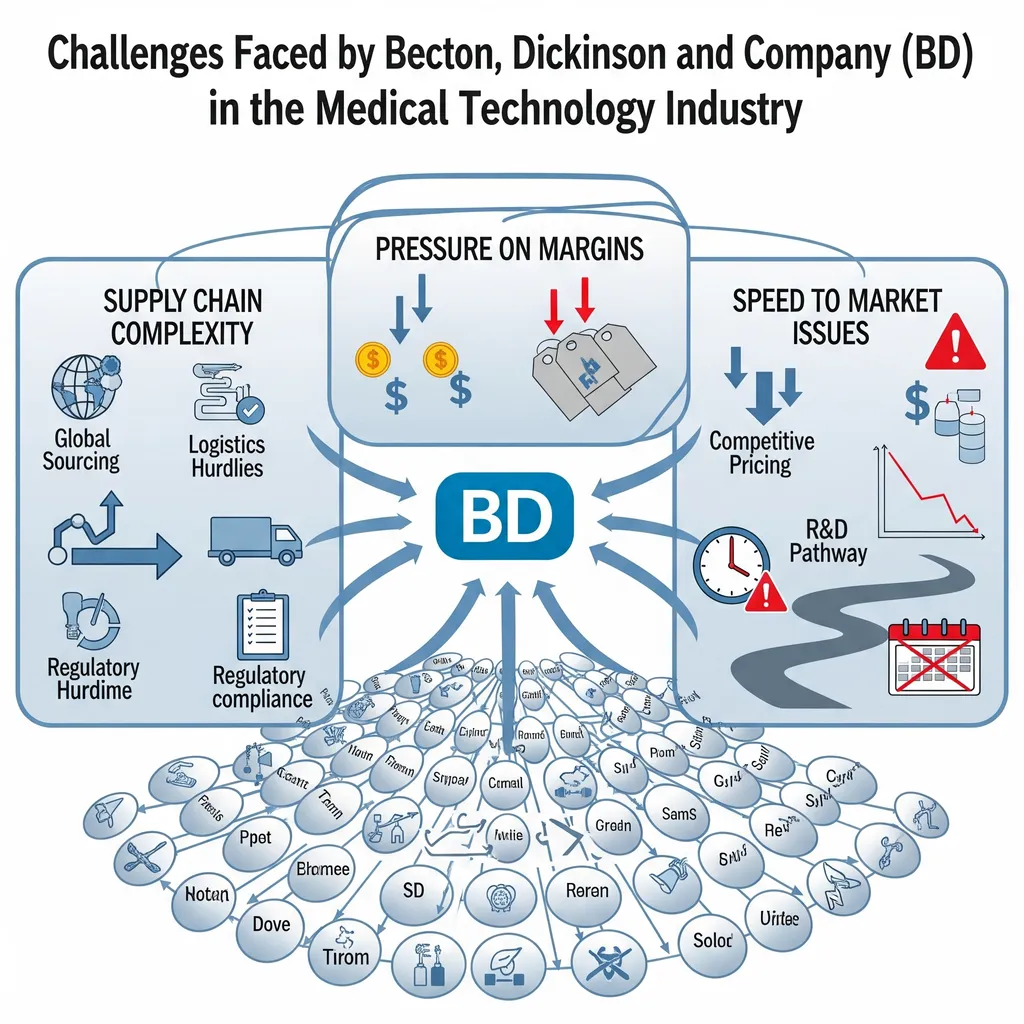

Case Study 2: Accelerating Digital Transformation in Pharma Manufacturing

The Company leading in global medical technology and pharmaceutical device manufacturer launched a Smart Enterprise program to increase speed, productivity, and quality. Challenges included:

Supply Chain Complexity: Managing a complex network of raw materials, manufacturing, and distribution.

Pressure on Margins: The need for relentless focus on operational efficiency and waste reduction.

Speed to Market: The ability to quickly launch new products is a key competitive differentiator.

The SIRI Assessment Process

Company decided to use SIRI to benchmark its key production facility in Singapore. The SA workshops were notably cross-functional, including participants from production, logistics, procurement, sales, and marketing to ensure a full value-chain perspective.

Key Findings & Prioritized Dimensions The assessment revealed that while the Company had invested in several Industry 4.0 initiatives, SIRI’s review uncovered “new dimensions” for potential gains: Low Scores: The plant scored poorly in D2: Horizontal Integration. Data sharing with external partners like suppliers was largely manual. This was identified as the root cause of supply chain visibility issues. Inconsistent Scores: Scores for D4: Shop Floor Automation varied widely across different lines, highlighting an opportunity to scale best practices. Prioritization: During the Prioritisation Matrix exercise, leadership ranked KPIs such as On-Time In-Full (OTIF) delivery and forecast accuracy as their highest Essential Business Objectives. This analysis overwhelmingly pointed to D2: Horizontal Integration as the number one priority.

Transformation Roadmap & Business Impact The insights enabled BD to formulate a cohesive transformation strategy:

Phase 1: Create Supply Chain Visibility: Address D2: Horizontal Integration by implementing a cloud-based supply chain control tower to integrate data from key suppliers, providing real-time visibility.

Phase 2: Implement Intelligent Forecasting: To improve D11: Enterprise Intelligence, deploy an AI-powered demand forecasting engine to leverage new real-time data.

Phase 3: Standardize and Scale Automation: Develop a standardized automation playbook based on the best practices from its most mature lines to guide a phased rollout of solutions, targeting improvements in D4: Shop Floor Automation.

Conclusion: Charting a Course for a Future Ready Enterprise

SIRI as a Catalyst for Sustainable Transformation

The Smart Industry Readiness Index (SIRI) is demonstrably more than a static assessment tool; it is a dynamic management framework that provides a structured, repeatable process for strategic evolution. In a manufacturing landscape often characterized by ad-hoc initiatives and anecdote-based decision making, SIRI introduces a standardized, data-driven methodology that brings clarity, alignment, and focus to the complexities of Industry 4.0. Its holistic approach, encompassing Process, Technology, and Organisation, ensures that transformation is treated not as a series of isolated projects but as a comprehensive program of organizational change

The Path Forward for Manufacturers

For senior leadership teams contemplating the journey toward a smart manufacturing future, the findings of this report yield several clear, strategic recommendations:

Embrace the Journey, Not Just the Destination:

The Official SIRI Assessment should be viewed not as a final exam but as the critical first step in a long-term commitment to transformation. The true value lies in the ongoing process of re evaluation and refinement that the LEAD framework encourages.

Champion from the Top: A successful digital transformation is fundamentally a change management exercise that requires unwavering commitment and sponsorship from the highest levels of leadership. The C-suite must not only approve the investment but also actively champion the cultural and organizational shifts necessary to realize its full value.

Empower the Entire Organization: The clarity provided by the SIRI roadmap is a powerful tool for empowerment. Leaders should use it to delegate responsibility, foster cross-functional collaboration, and make targeted investments in workforce development. A future-ready enterprise is one where every employee understands the strategic direction and is equipped with the skills to contribute to it. In conclusion,SIRI provides manufacturers the essential compass to navigate Industry 4.0, enabling confident digital transformation through proven methodology and organizational alignment.