IndustryOS®: A Scalable Universal Manufacturing Operating System (UMOS) Built on the ISA-95 Standard

IndustryOS®: A Scalable Universal Manufacturing Operating System (UMOS) Built on the ISA-95 Standard

From Digital Chaos to a Unified Manufacturing ⇲ Backbone

In the era of Industry 4.0, the modern manufacturing enterprise is drowning in data yet starved for wisdom. A significant chasm has long separated the corporate office from the plant floor. The enterprise, with its Resource Planning (ERP) systems, speaks the language of finance, orders, and logistics. The factory, with its Operational Technology (OT), speaks the language of sensor readings, machine states, and process variables. This IT/OT divide has created a state of digital chaos a persistent source of inefficiency, strategic misalignment, and costly, brittle custom integrations. To thrive in this new competitive landscape, manufacturers require a single pane of glass, a unified digital backbone that weaves a consistent digital thread from the top floor to the shop floor, translating data into actionable intelligence at every step.

The ISA-95 Foundation: Architecting for Universal Scalability

To understand how a software platform can achieve universal scalability, one must first appreciate the framework that makes universal communication and data modelling in manufacturing possible. The ANSI/ISA-95 standard (or IEC 62264) provides the lingua franca of modern manufacturing. Its fundamental purpose is to solve the costly and error-prone problem of making business and manufacturing systems communicate effectively by providing three pillars of standardization: consistent terminology, consistent information models, and consistent operations models.

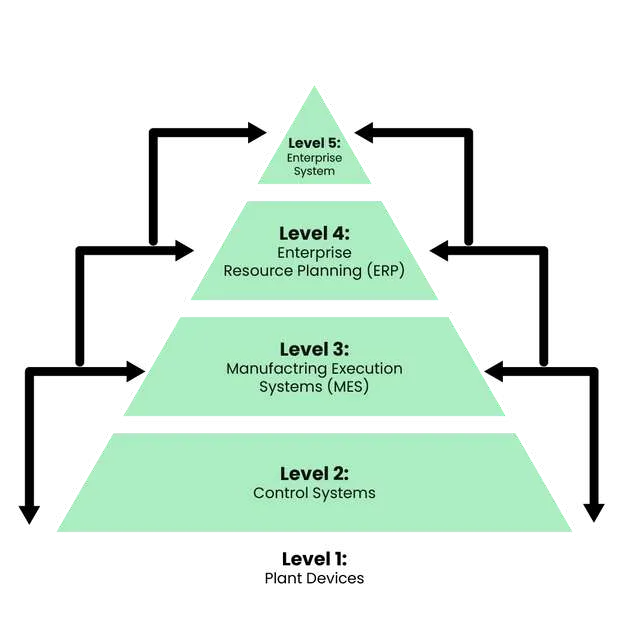

Secondly, the standard’s five-level Automation Pyramid, based on the venerable Purdue Reference Model, provides a brilliant model for data abstraction and contextualization. It creates a logical structure for transforming millions of raw, high-frequency data points from the plant floor into aggregated, context-rich information for enterprise systems.

Table: The ISA-95 Hierarchical Levels (The Automation Pyramid)

| Level | Level Name | Primary Function/ Activities | Typical Timeframe | Example Systems/ Technologies |

|---|---|---|---|---|

| Level 4 | Business Planning & Logistics | Establishing business schedules, operational planning, order processing, inventory and financial management. | Months, Weeks, Days | Enterprise Resource Planning (ERP), Customer Relationship Management (CRM), Supply Chain Management (SCM) |

| Level 3 | Manufacturing Operations Management (MOM) | Managing production workflows, detailed scheduling, dispatching, resource allocation, recipe execution, performance tracking. | Days, Shifts, Hours, Minutes, Seconds | Manufacturing Execution Systems (MES), Laboratory Information Management Systems (LIMS), Warehouse Management Systems (WMS) |

| Level 2 | Monitoring & Control | Supervising, monitoring, and controlling the physical process in real-time. Executing control recipes and logic. | Seconds, Sub-seconds | Programmable Logic Controllers (PLC), Distributed Control Systems (DCS), Supervisory Control and Data Acquisition (SCADA) |

| Level 1 | Sensing & Manipulation | Sensing process variables (e.g., temperature, pressure) and manipulating control elements (e.g., valves, motors). | Seconds, Milliseconds | Smart Sensors, Actuators, Analysers, Intelligent I/O Devices |

| Level 0 | The Physical Process | The actual physical equipment and processes involved in manufacturing. | Milliseconds, Microseconds | Motors, Valves, Pumps, Reactors, Conveyors, Robotic Arms |

Finally, the standard is functionally comprehensive. It is a cohesive suite of multiple parts, each addressing a specific integration challenge, from high-level concepts to detailed transaction specifications.

Table: Overview of the ANSI/ISA-95 Standard Suite

| Part Number | Full Title | Core Purpose |

|---|---|---|

| ANSI/ISA–95.00.01 | Models and Terminology | Establishes the foundational vocabulary and conceptual models, including the hierarchical framework, for defining the enterprise-control interface. |

| ANSI/ISA–95.00.02 | Objects and Attributes for Enterprise-Control System Integration | Defines the detailed data structures (objects and their attributes) for the key manufacturing resources (Personnel, Equipment, Material) exchanged between Level 4 & Level 3. |

| ANSI/ISA–95.00.03 | Activity Models of Manufacturing Operations Management | Defines the standard activities and functions within Level 3 (MOM), covering Production, Quality, Maintenance, and Inventory operations. |

| ANSI/ISA–95.00.04 | Objects and Attributes for MOM Integration | Defines the detailed data structures (objects and attributes) used for information exchange between the MOM activities defined in Part 3. |

| ANSI/ISA–95.00.05 | Business-to-Manufacturing Transactions | Specifies the dynamic information exchanges (transactions) between Level 4 and Level 3 systems, defining the content and structure of messages. |

| ANSI/ISA–95.00.06 | Messaging Service Model (MSM) | Defines a technology-independent model for the messaging services required to execute the transactions from Part 5, ensuring interoperability and consistency. |

The IndustryOS® Architecture: A Manufacturing Knowledge Graph in Practice

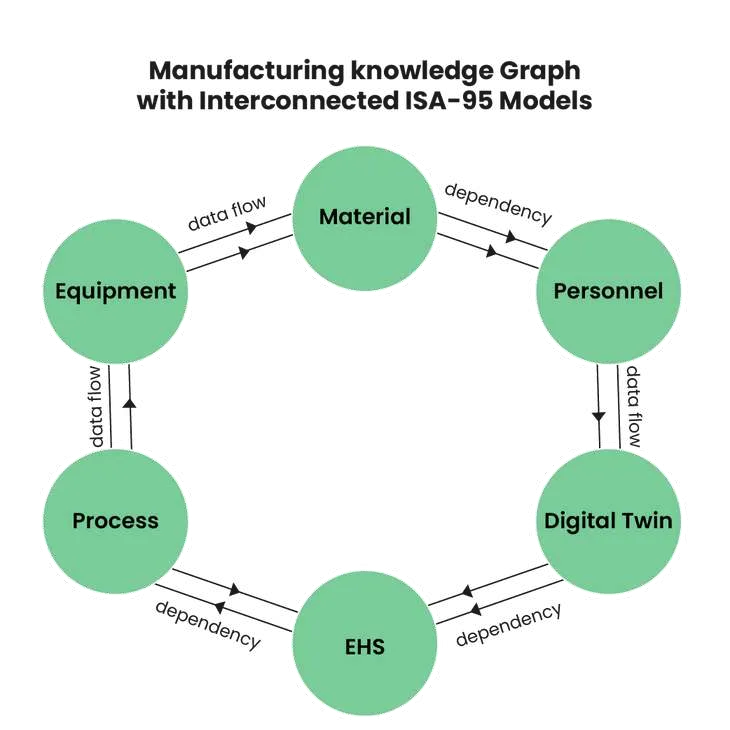

The platform’s Entity-Relationship architecture is a direct translation of these standard ISA-95 models. It includes a robust Equipment Model implementing the full ISA-95 hierarchy, a Material Model for complete bi-directional traceability, and a Personnel Model for skills and compliance management. While these models define the ‘who, what, and where’ of manufacturing, the true operational intelligence comes from the Process and Production Model, the dynamic core that orchestrates all manufacturing activities. This central model defines entities like WorkOrder and ProductionPerformance and links them to equipment, materials, and personnel, forming the core MES functionality of the platform.

Table: IndustryOS® Data Model Dictionary (Sample)

| Entity Name | Description | Attribute Name | Data Type | Constraints | Example Value | Relationship |

|---|---|---|---|---|---|---|

| Equipment Module | A logical piece of equipment that performs a specific function. | EquipmentID | INT | PK, Not Null | 101 | Part of a Unit. |

| Equipment Name | VARCHAR(100) | Not Null | "Reactor R-101" | |||

| Material Lot | A specific, traceable quantity of a material. | LotID | VARCHAR(50) | PK, Not Null | "RM-XYZ-20240826-01" | Instance of a Material Definition. |

| Quantity | DECIMAL(10,2) | Not Null | 1500 | |||

| Work Order | An executable order to produce a specific quantity of a material. | WorkOrderID | INT | PK, Not Null | 5001 | Generated from Production Schedule. |

| Status | VARCHAR(20) | Not Null | "In Progress" | |||

| Emission Record | A record of a specific emission event or period. | RecordID | INT | PK, Not Null | 87345 | |

| WorkOrderID | INT | FK | 5001 | Links to Work Order. Work Order ID. | ||

| Analytical Model | A computational or machine learning model used for analysis. | ModelID | INT | PK, Not Null | 701 | |

| ModelName | VARCHAR(100) | Not Null | "R-101 Bearing Failure Predictor" |

The iLOL® Interface ⇲ : Making the Standard Tangible and Intuitive

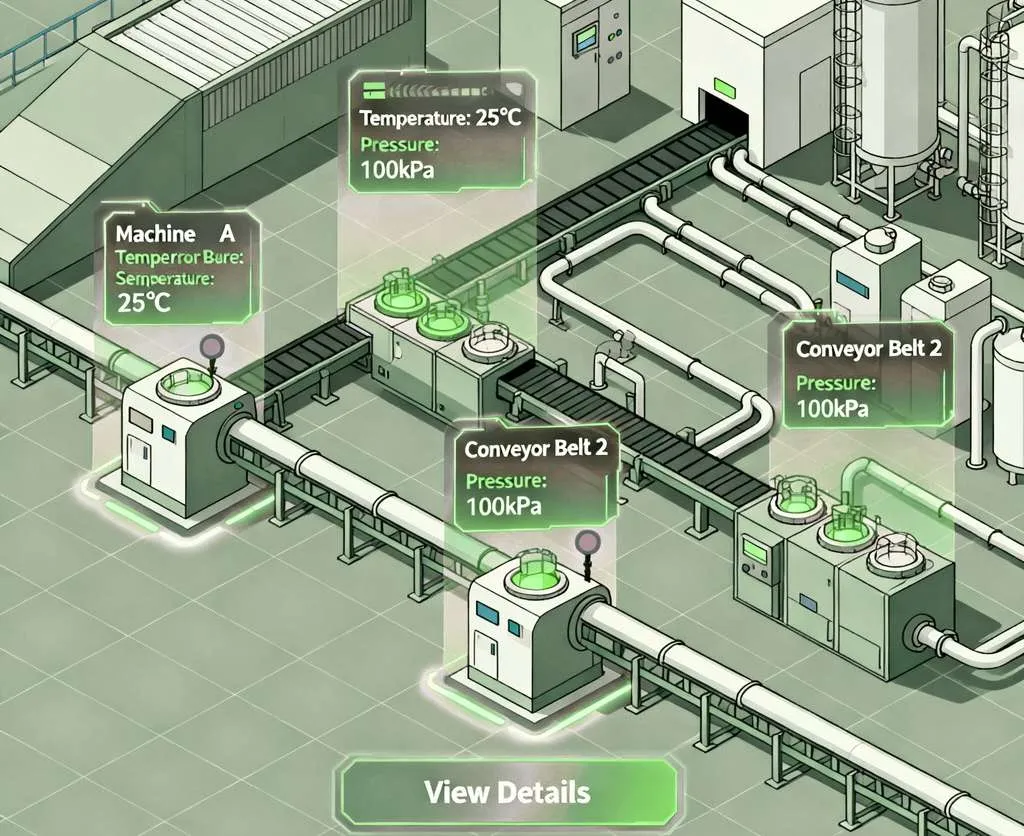

- Static Data: This includes foundational, relatively unchanging information such as machine layouts, hazardous area maps, P&IDs, and detailed equipment specifications (e.g., design parameters, technical details, financial data).12 This static information forms the standardized, reliable baseline for the digital twin.

- Dynamic Data: This captures real-time, high-frequency information from sources like IoT sensors (monitoring temperature, pressure, vibration, etc.), machine control systems, and operator inputs (e.g., digital log sheets, quality checks).12 This dynamic data is layered on top of the static model to reflect the current state and performance of the physical counterpart.

Platform Modules

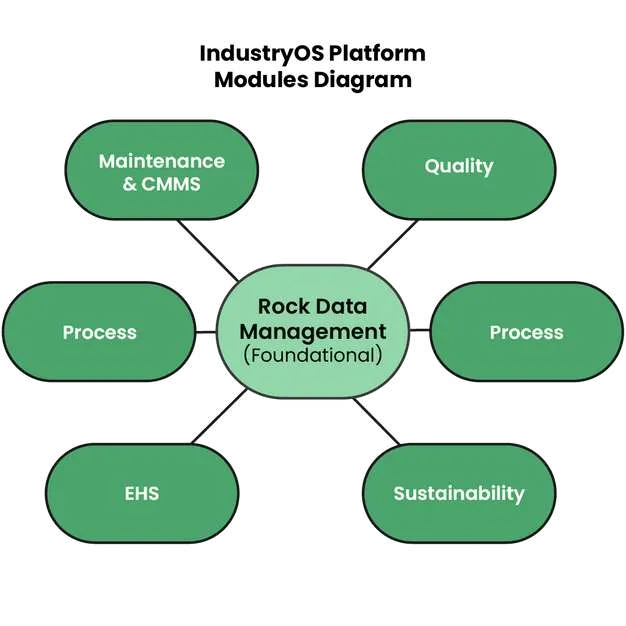

- IndustryOS® Rock: This is the foundational data management system. It provides the core functionality for creating the digital twin, using the iLOL® concept to model the plant, assets, and their interconnections. It serves as the central database and asset registry for the entire platform.

- Functional Modules: The platform offers specialized modules targeting specific areas of manufacturing operations

- Maintenance & CMMS: Provides solutions for preventive and breakdown maintenance, TPM compliance, and optimizing metrics like Mean Time Between Failures (MTBF) and Mean Time To Repair (MTTR).

- Quality Optimization: Designed to streamline operations to improve manufacturing quality, minimize defects, and ensure first-pass success.

- Process Optimization: Offers tools for process and safety management with the goal of increasing OEE. EHS (Environment, Health, and Safety): Provides tools for managing workplace safety, compliance, audits, and incident reporting. Sustainability: Delivers insights to manage and report on sustainability metrics, such as carbon emissions and ESG frameworks.

Table: IndustryOS® ⇲ Module Alignment with ISA-95 Part 3 MOM Activities

| ISA–95 Part 3 MOM Category | Management Activity | IndustryOS® Module Alignment & Capabilities |

|---|---|---|

| Production Operations Management | Data Collection | Core capability. Collects static, workflow, and real-time dynamic data from sensors and control systems. |

| Performance Analysis | Core strength. Provides OEE, line effectiveness, and custom analytics and visualization. | |

| Quality Operations Management | All Activities | The “Quality Optimization” module is designed to streamline operations for superlative manufacturing quality, covering data collection and analysis. |

| Maintenance Operations Management | All Activities | Strong alignment. Provides preventive maintenance planner, breakdown & CAPA, and tracks MTBF/MTTR. |

| Inventory Operations Management | Tracking & Tracing | Handled via specialized integration with WMS/ERP systems, using ISA-95 as the data backbone. |

| Production Operations Management | Detailed Scheduling | Handled via specialized integration with Advanced Planning & Scheduling (APS) systems. |

Table: Example Business-to Manufacturing (B2M) Transactions (Part 5)

| Transaction Direction | Information Category (Noun) | Purpose | Example Data Elements |

|---|---|---|---|

| Level 4 -> Level 3 | Production Schedule | Instructs the manufacturing facility what to produce, the quantity, the required completion time, and the product definition to use. | Work Order ID, Product ID, Quantity, Start/End Dates, Bill of Material ID, Recipe ID. |

| Level 3 -> Level 4 | Production Performance | Reports the actual results of a production run back to the business systems for costing, inventory, and analysis. | Work Order ID, Actual Quantity Produced, Actual Materials Consumed, Actual Labor Hours, Scrap Quantity, Completion Time. |

| Level 4 -> Level 3 | Maintenance Request | Sends a request from the enterprise asset management system to the plant to perform maintenance on a piece of equipment. | Equipment ID, Maintenance Task Description, Required Completion Date, Priority Level. |

Measuring Success: A New Generation of KPIs

Table: The Universal KPI Framework for Manufacturing

|

KPI Name

|

Definition

|

Strategic Goal

|

KPI Type

|

|---|---|---|---|

| Overall Equipment Effectiveness (OEE) | A composite measure of asset productivity, based on availability, performance, and quality. | Maximize asset utilization and productivity. | Lagging |

| First Pass Yield (FPV) | The percentage of units that are completed to specification without any rework or scrap. | Improve process quality and stability. | Lagging |

| Mean Time Between Failures (MTBF) | The average operational time between equipment breakdowns. | Improve asset reliability and stability. | Lagging |

| Predicted Failure Rate | The AI-generated forecast of asset failures expected in a future period (e.g., next 30 days). | Proactively allocate maintenance resources. | Predictive |

| CO2e per Unit/Batch | The total kilograms of carbon dioxide equivalent emitted during the production of one unit or batch. | Reduce environmental impact, support sustainability goals. | Lagging |

| Optimized Schedule Adherence | The percentage of time that operations follow the AI-optimized production schedule designed to avoid predicted disruptions. | Maximize operational resilience and output. | Prescriptive |

Conclusion: True Scalability Through a Universal Standard

- 1.A Common Language: By using ISA-95’s information models as its native data structure, IndustryOS® can represent any manufacturing environment, from chemical processing to discrete assembly, within a single, consistent framework.

- 2.Inherent Contextual Intelligence: Its deep implementation of the ISA-95 hierarchy allows it to process and contextualize data with equal effectiveness for a single production line or a global network of fifty factories.

- 3.Interoperability by Design: Its adherence to ISA-95 transaction models ensures it can serve as a robust, reliable hub in any enterprise’s IT/OT ecosystem.